Rinnai Lower Costs And Environmental Impact For Expanding Launderette Group

Rinnai has recently provided a high efficiency water heating solution to a South Wales launderette which needed to replace its old gas boiler as the property wanted to lower operational costs and drive down emissions.

The new owner wants to install new coin-activated washing machines and increase its capacity for more customers. The increase in customers would logically mean an increase in peak demand loading for the hot water delivery system.

The launderette has planned to have 10 washing machines in total but with 2 different models differing in size and hot water consumption.

The site currently employs a low Kw rating gas boiler with 144 liters of built-in internal storage. The current system is only capable of providing 154 liters of peak demand. The new additions of coin-operated washing machines see peak demand increase the loading of hot water delivery to a requirement of 276 liters

The new hot water delivery system needed to reach 276 liters on demand and be able to recover from peak demand conditions within 40 minutes – the average cycle of a coin operated commercial washing machine.

With a peak demand of 276L already determined, Rinnai UK was able to propose a system consisting of an N1300 continuous flow water heater with an additional 300L storage buffer to hold the peak demand for the washing machines. This system can recover the entire buffer in as little as 23 minutes, meaning this system is also able to cope with any further expansion by the customer as the buffer exceeds the peak demand.

Rinnai can demonstrate the benefits of the N1300 system with the graphs below. One highlights the reduction of harmful emissions whilst the other graph proves the financial benefits of purchasing a Rinnai N1300 system. Both graphs measure the benefits over a 5-year period.

The first graph details how much less emissions are released by the Rinnai N1300 system when compared to the currently installed system. Over five years Rinnai’s N1300 offers a 17% decrease in costs.

DHW System – Carbon Emissions Lifecycle

The Graph below illustrates the difference over 5 years when comparing Rinnai’s N1300 to the currently installed system in terms of OPEX costs (cumulative running costs). The Rinnai N1300 will require £13,543.81, whilst the competitor system will cost £16,281.39. This means Rinnai can reduce 5-year operating costs by 17%.

DHW System – Cumulative Running Costs (OPEX)

.

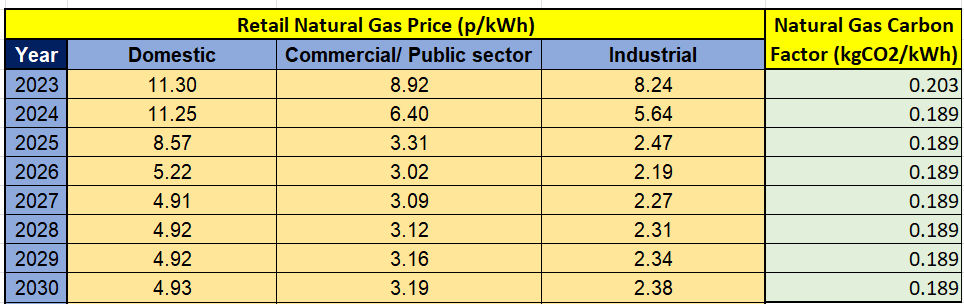

Gas – Prices & Carbon Factor

These are the forecasted gas prices as provided by the Department for Energy Security and Net Zero. More can be seen using the following link: Green Book supplementary guidance: valuation of energy use and greenhouse gas emissions for appraisal - GOV.UK (www.gov.uk)

Rinnai will continue to provide low cost, feasible and technical solutions for any commercial premises aiming to maximise daily operations. Rinnai technology is designed to produce total system efficiency meaning that commercial operators can rely on Rinnai systems to elevate operational output at a reduced cost.

RINNAI FULL PRODUCT AVAILABILITY 24/7 FOR NEXT DAY DELIVERY of ALL HOT WATER HEATING UNIT MODELS INCLUDING 48-58kW UNITS-

SAVINGS OF

20% REDUCTION of opex cost,

30% REDUCTION of initial cost

15% REDUCTION in carbon

75% REDUCTION of space

For more information on the RINNAI product range visit www.rinnai-uk.co.uk Or email engineer@rinaiuk.com