High Performing Buildings – October’s Roundup

This month’s high performing buildings roundup includes state-of-the-art offices in Shanghai and a new wooden landmark building in Helsinki. Watch the...

Read Full Article

A pioneering research building at the University of Freiburg is being hailed as a best-in-class example of a robotically manufactured sustainable building.

The building itself is a research project of the Integrative Computational Design and Construction for Architecture (IntCDC) at the University of Stuttgart and Living, Adaptive and Energy-autonomous Materials Systems (livMatS) at the University of Freiburg, which are investigating an integrative approach to design and construction for sustainable architecture.

The livMatS Biomimetic Shell at the FIT Freiburg Center for Interactive Materials and Bioinspired Technologies is a fully deconstructible and reusable building. Designed to be easily dismantled and reused, it is built from sustainable timber. Compared to a conventional timber building, the FIT Biomimetic Shell reduces the total environmental life cycle impact by 50 per cent.

Picture: a photograph of the livMatS Biomimetic Shell exterior. Image Credit: Roland Halbe

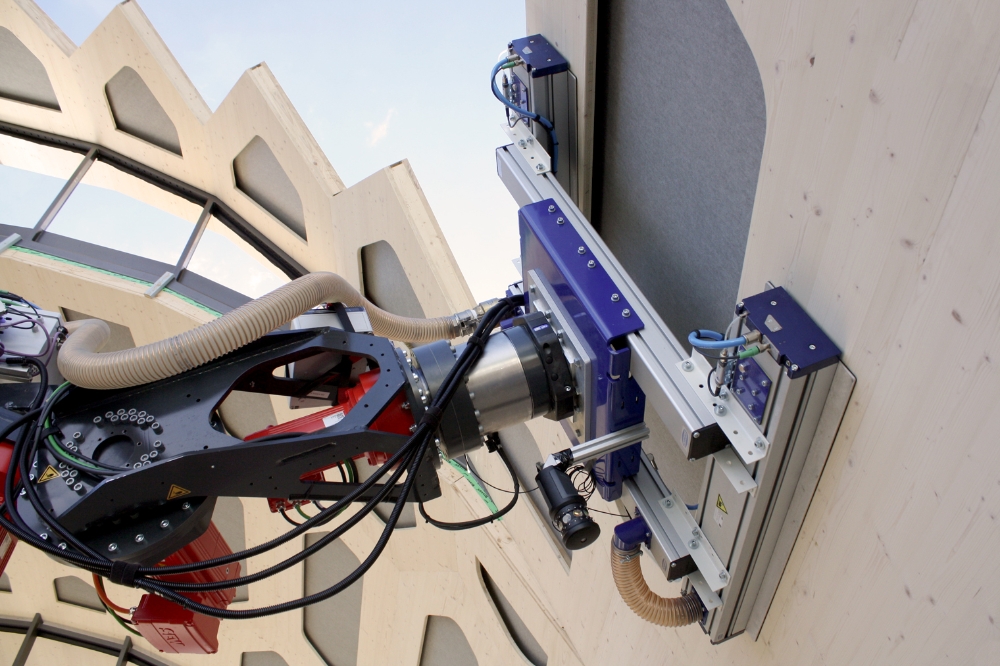

The building is made up of segmental shells which were suitable for assembly on-site due to the high precision in prefabrication and the low component weight. The assembly method consists of a robotic spider crane that picks up components with a vacuum gripper, automatically places them at the corresponding installation position and holds them in position until they are also automatically screwed together. A second spider crane equipped with a new type of screw effector automatically approaches the edges to be screwed and inserts all screws. To ensure quality assurance a digital scan of selected cassettes was created using a terrestrial laser scanner, which could then be compared with the target design geometry. These measurements were carried out both after production, immediately before assembly on the construction site, and in the installed state. A scan of the finished shell was also taken to finally evaluate the geometry.

"This form of human-machine interaction in the manufacturing process enables the effective, digitally controlled production of complex components with a high degree of precision," said Professor Achim Menges from the Institute for Computational Design and Construction (ICD) and spokesperson for the IntCDC Cluster of Excellence at the University of Stuttgart.

Embedded in the timber shell is the "Solar Gate", a large-scale skylight which contributes to the regulation of the indoor climate by means of a biomimetic, energy-autonomous, 4D-printed shading system. This "solar gate" is modelled on pine cones, which open and close in a moisture-controlled manner.

A weather-responsive shading system on the skylight also regulates the building's climate by shielding the interior from high heat loads in summer while allowing solar gains in winter. This allows the material structure of the shading elements to self-shape in response to changes in daily and seasonal weather cycles to regulate the indoor climate. The 424 self-shaping shading elements are made of bio-based materials and are located in 10m² box windows at the skylight. These were programmed using a 4D-printing process to provide year-round solar shading while harvesting solar heat without requiring any operating energy. Together, the Solar Gate's weather-responsive façade, highly insulated building envelope and activated floor slab create a thermally comfortable space year-round without the need for any other HVAC equipment.

"Our goal is to operate the pavilion in an energy-neutral way," says Professor Jürgen Rühe from the Department of Microsystems Engineering and member of the spokesperson team of the livMatS Cluster of Excellence at the University of Freiburg.

"In the future, we will also explore other solutions for designing building facades that can adapt to changing environmental conditions, such as temperature. In this way, we can create a pleasant indoor climate and enable the building to operate in a CO2-neutral manner.”

Picture: a photograph of a robotic arm during the construction. Image Credit: ICD/ITKE/IntCDC University of Stuttgart

Article written by Ella Tansley | Published 26 July 2023

This month’s high performing buildings roundup includes state-of-the-art offices in Shanghai and a new wooden landmark building in Helsinki. Watch the...

Read Full ArticlePlans for an office building with a ‘timber superstructure”, the first of its kind in Maidenhead and the wider Thames Valley, have been submitted. Designed...

Read Full ArticleThisWeekinFM’s high performing buildings roundup features projects in the Czech Republic, including an environmentally conscious building for a forest management...

Read Full ArticleAviva Investors’ Grade II listed Victorian HQ has undergone an extensive refurbishment. 134-46 Curtain House in Shoreditch was built between 1881 and...

Read Full ArticleThe new Asllan Rusi sports palace in Albania is set to become a new landmark for the city of Tirana. Architect MVRDV has won the competition to design what’s...

Read Full ArticleNew York’s skyline has just got an eco-friendly upgrade with the opening of 270 Park Avenue – the new state-of-the-art global headquarters for...

Read Full ArticleA new 23-storey office building at One Cutler Street in the City of London will be delivered by contractor Multiplex. Brockton Everlast has selected Multiplex under a...

Read Full ArticleThe British Council for Offices’ annual National Awards have revealed an exciting shift in office design – customer experience taking centre stage. For the...

Read Full ArticleCBRE Investment Management has transformed 30 Semple Street into a game-changer for sustainable offices in Scotland. The building, situated in the Fountainbridge area...

Read Full ArticleGrand Bayview Qianhai, a two tower apartment building in Shenzhen, China, is an example of a new building typology that specifically targets isolated city...

Read Full Article