New Business Waste Separation Rules – What You Need to Know

As of 31 March 2025, workplaces in England will need to change how they manage their waste. These new requirements will affect how companies handle their...

Read Full Article

Single-use plastics might have more inherent value than you think. Researchers have developed a new method for upcycling abundant, seemingly low-value plastics into high-quality liquid products, such as motor oils, lubricants, detergents and even cosmetics.

The discovery also improves on current recycling methods that result in cheap, low-quality plastic products.

The Northwestern University of Illinois, the Argonne National Laboratory and Ames Laboratory led the multi-institutional team in the USA.

“Our team is delighted to have discovered this new technology that will help us get ahead of the mounting issue of plastic waste accumulation,” said Northwestern’s Kenneth R. Poeppelmeier, who contributed to the research.

“Our findings have broad implications for developing a future in which we can continue to benefit from plastic materials but do so in a way that is sustainable and less harmful to the environment and potentially human health.”

ACS Central Science

Poeppelmeier co-led the work with Aaron D. Sadow, a scientist in the Division of Chemical and Biological Sciences at Ames Laboratory, and Massimiliano Delferro, group leader of Argonne National Laboratory’s catalysis program. The study was published on October 23 in the journal ACS Central Science.

The plastic problem

Each year, 380 million tons of plastic are created worldwide. And as the plastics market continues to increase, many analysts predict production could quadruple by 2050. More than 75% of these plastic materials are discarded after one use. Many of them end up in our oceans and waterways, harming wildlife and spreading toxins.

“There are certainly things we can do as a society to reduce consumption of plastics in some cases,” Sadow said. “But there will always be instances where plastics are difficult to replace, so we really want to see what we can do to find value in the waste.

"Our findings have broad implications for developing a future in which we can continue to benefit from plastic materials, yet do so in a way that is sustainable and less harmful to the environment and potentially human health.”

Down-cycling

While plastics can be melted and reprocessed, this type of recycling yields lower-value materials that are not as structurally strong as the original material. Examples include down-cycling plastic bottles into a moulded park bench.

Bonds

When left in the wild or in landfills, plastics do not degrade because they have very strong carbon-carbon bonds. Instead, they break up into smaller plastics - microplastics. Whereas some people see these strong bonds as a problem, the Northwestern, Argonne National Laboratory and Ames Laboratory team saw this as an opportunity.

“We sought to recoup the high energy that holds those bonds together by catalytically converting the polyethylene molecules into value-added commercial products,” Delferro said.

A catalytic solution

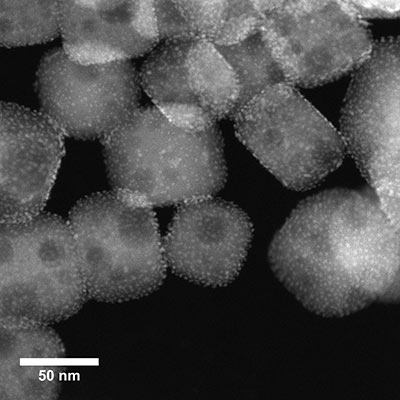

The catalyst consists of platinum nanoparticles - just two nanometers in size - deposited onto perovskite nanocubes, which are about 50-60 nanometers in size. The team chose perovskite because it is stable under the high temperatures and pressures and an exceptionally good material for energy conversion. (A perovskite is any material with the same type of crystal structure as calcium titanium oxide.) To deposit nanoparticles onto the nanocubes, the team used atomic layer deposition, a technique developed at Argonne that allows precise control of nanoparticles.

Liquid hydrocarbons

Under moderate pressure and temperature, the catalyst cleaved plastic’s carbon-carbon bond to produce high-quality liquid hydrocarbons. These liquids could be used in motor oil, lubricants or waxes or further processed to make ingredients for detergents and cosmetics. This contrasts commercially available catalysts, which generated lower quality products with many short hydrocarbons, limiting the products’ usefulness.

Even better - the catalytic method produced far less waste in the process. Recycling methods that melt plastic or uses conventional catalysts generate greenhouse gases and toxic byproducts.

Picture: Low-value plastics can be turned into motor oils, lubricants, detergents and even cosmetics with the help of science and the platinum nanoparticles pictured below.

Article written by Brian Shillibeer | Published 30 October 2019

As of 31 March 2025, workplaces in England will need to change how they manage their waste. These new requirements will affect how companies handle their...

Read Full ArticleCommercial cleaning social enterprise NGB Clean is making use of discarded inner tubes and tyres dumped in their clients’ office bike stores. NGB Clean, a...

Read Full ArticleNearly 1 million tonnes of plastic packaging waste could be avoided by standardising materials within the next five years, according to a new report. Watch...

Read Full ArticleA waste management company is rewarding correct waste segregation in workplaces by linking it to a weekly prize jackpot. SmartSegregation offers entry into weekly...

Read Full ArticleESG Pro Limited will partner with Full Bin in the United Arab Emirates and MENA region. Full Bin, known for its waste management and recycling services, will use its...

Read Full ArticleA UK-based lighting designer and manufacturer is extending its sustainability efforts by offering its “carbon careful” luminaire refurbishing service to other...

Read Full ArticleOklahoma City has become the first city in Oklahoma, and third in the USA, to earn the WELL Health-Safety Rating for Facility Operations and Management across a portfolio...

Read Full ArticleAs the government prepares for a consultation on the safety of disposable vapes, waste management provider Reconomy has launched a new recycling programme for...

Read Full ArticleThe Liverpool branch of YMCA Together has been gifted surplus furniture from a McDonald’s restaurant in Lymm, Warrington. In 2022, Reconomy was awarded sole...

Read Full ArticleA waste management and recycling SaaS platform designed to enhance the way businesses in the UK handle waste disposal is now live in the UK. Full Bin’s service...

Read Full Article