- Content

- People

- Unsafe Working Environments In The IT Industry Risk People’s Health

11 February 2020

Problematic factory conditions, including excessive working hours, forced labour and discrimination continue to risk workers’ health in the IT industry, according to a TCO Development report.

In the 20 factories that were audited, 109 non-conformities related to factory conditions were found initially. These spanned health and safety (51 incidents), labour rights (54 incidents) and code of conduct communication (4 incidents). After initial corrective action plans, 77% of these were eliminated, and of the 25 left, seven were categorised as minor and 18 were major.

A major non-conformity is defined as “significant failure, affecting the system’s ability to produce the desired results.” in the report entitled "Impacts and Insights 2019".

Growing pressure on industry

The findings are based on reports from independent verifiers, interviews with brand owner senior management representatives and independent factory audits. Improvements affected the working conditions of approximately 46,600 workers.

It seems that achieving a more socially sustainable industry requires long term investments, follow-up and clear consequences that encourage action. This can be challenging in such a fast-moving industry, as the report states:

“Much of IT product manufacturing is carried out in low-cost, low-wage countries, where workers are often less protected and employment less regulated. Shorter product cycles and growing demand for new technologies place added pressure on industry to deliver new devices faster and at a lower cost. The result can be poor working conditions throughout the supply chain, putting human health and worker safety at risk.”

“Real change demands engagement from the brand owner. We put pressure on the IT industry and can withdraw certificates and restrict factories from manufacturing certified products if the criteria in TCO Certified aren’t fulfilled”

–Sören Enholm

CEO, TCO Development

Procurement must drive industry improvements

More and more, those responsible for IT procurement are using their leverage to directly drive industry improvements in supply chain responsibility, supported by the manufacturing criteria in TCO Certified

“Succeeding with sustainable procurement of IT products is a challenge.” says Helena Babelon, Head of IT Sustainability & Continuous Improvement at Electrolux Group.

“Independent verification of compliance is crucial for a credible result. We’ve decided to use TCO Certified, it makes the procurement process much more efficient and helps us set criteria in a straightforward way,”

The report presents a number of solutions to solving sustainability issues in the IT industry. An independent party must audit factories, effective corrective action plans must be implemented and to avoid the recurrence of problems, and root causes must be found. TCO Development believe that truly sustainable and workable change must come from the top:

“Real change demands engagement from the brand owner. We put pressure on the IT industry and can withdraw certificates and restrict factories from manufacturing certified products if the criteria in TCO Certified aren’t fulfilled,” says Sören Enholm, CEO at TCO Development.

You can read the full report here

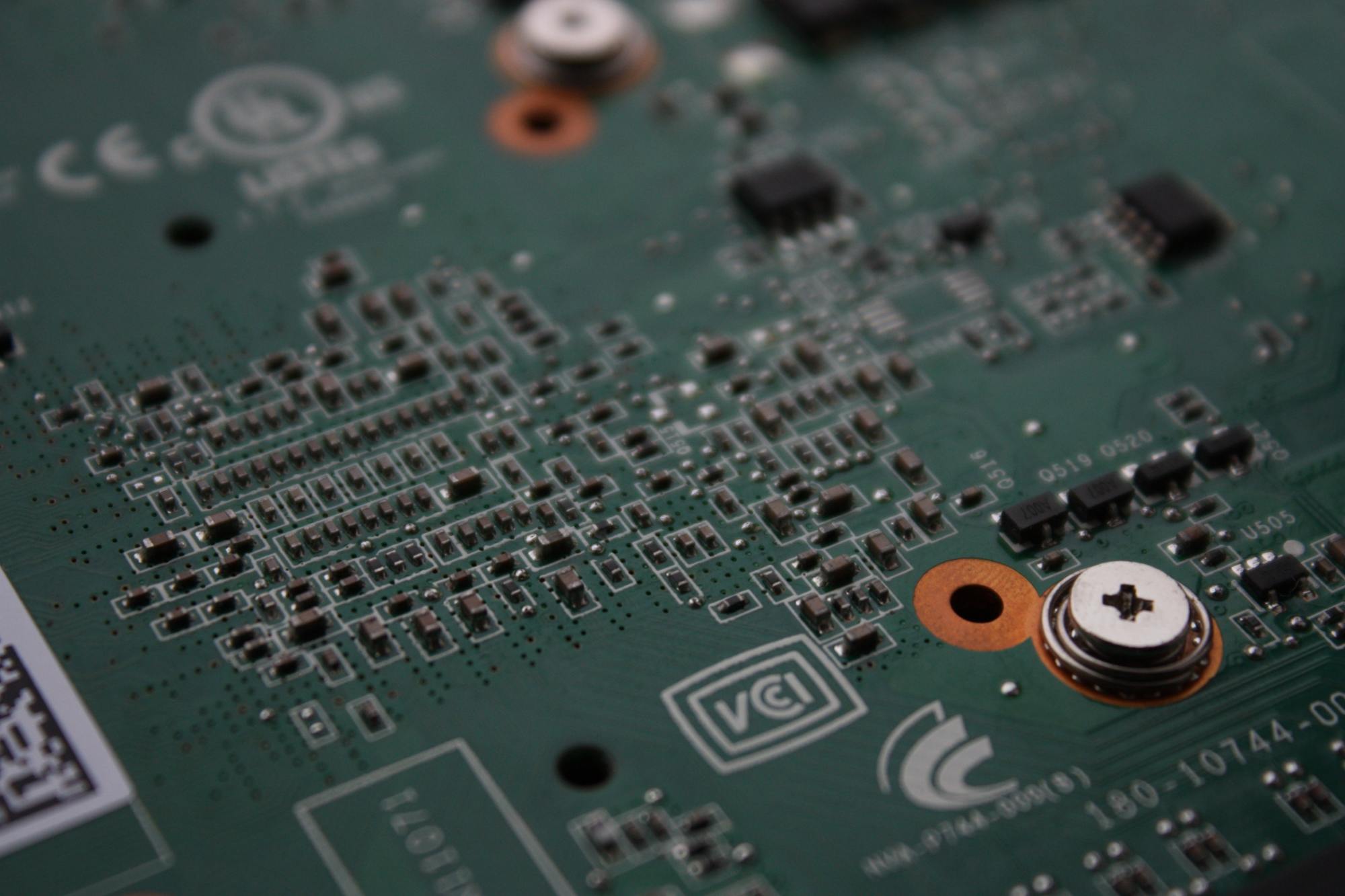

Picture: Unsafe Working Environments In The IT Industry Risk People’s Health

Article written by Ella Tansley | Published 11 February 2020

Share

Related Articles

Corporate Spending with Social Enterprises Increases 46% in 9th Year of Buy Social Challenge

33 businesses, including Amey, CBRE, Compass Group, Equans, Mitie, Sodexo and Willmott Dixon, collectively spent £179 million with social enterprise suppliers in...

Read Full Article

New Rating System Will Rank Cement and Concrete Based on Carbon Footprint

The Global Cement and Concrete Association is driving the procurement of more sustainable cement and concrete with a first-of-its-kind global carbon rating...

Read Full Article

Last Chance to Enter CBRE Supplier Partner Innovation Challenge 2025

Contractors and suppliers working in FM and the built environment have until 31 January to submit their business for the CBRE UK Supplier Partner Innovation Challenge...

Read Full Article

New Database Shows Environmental Impact of Construction Materials

Construction professionals now have access to the industry’s largest dataset of eco-friendly materials, featuring over 250,000 products.

The resource,...

Read Full Article

Five Social Sustainability Questions Every Business Must Ask Their Supply Chains

Ensuring a commitment to health and safety is a well-established practice. But companies are increasingly being held accountable for their suppliers' sustainability...

Read Full Article

Sodexo Issues Net-Zero Deadline to Suppliers

Sodexo has stated that it will only work with suppliers who demonstrate tangible net-zero progress “through published reporting” in the future.

As part of...

Read Full Article

Almost £100m Spent With Social Enterprises in Buy Social Corporate Challenge

A project supported by FM and commercial property companies such as Amey, CBRE, Compass, Equans, Mitie, Wates Group and Willmott Dixon has hit a £99 million...

Read Full Article

Predictions for Supply Chain Issues in 2023

Alex Minett from CHAS, the supply chain risk management company, looks at seven issues that will affect supply chains in 2023.

The last year has been challenging...

Read Full Article

More Than Supply Chain – Measuring Scope 3 Emissions

Scope 3 emissions can be the largest part of an organisation’s carbon footprint – but there remains confusion over the true definition of this emission...

Read Full Article

Stonewall Fills Virtual World Cup Stadium For LGBTQ+ Rights

LGBTQ+ rights charity Stonewall has created a virtual football stadium, in protest against the injustices that this community faces in Qatar, and in many more...

Read Full Article

.gif)

.gif)

.gif)

.png)

.png)